Connected Mobile Machines

powered by Ardexa

Remote access and Remote monitoring – we offer a complete solution from a single source in cooperation with Ardexa.

All functions with one platform

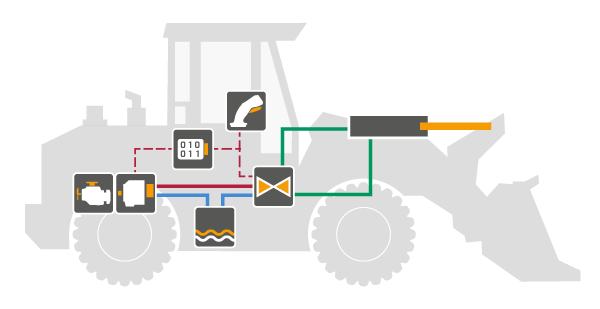

The challenge of mobile machines

Mobile machines differ from stationary machines in many ways:

- They are used outdoors, in almost any weather and in sometimes very harsh conditions such as forests, quarries, tunnels, mountains.

- The load ranges of the assemblies of off-road machines are very different and very dynamic.

- The dimensioning of mobile machines is subject to many constraints (weight, energy consumption, size, road traffic regulations, etc.).

- The manufacturers (OEM) are often SMEs to medium-sized companies and produce small to medium quantities.

- Functionality, automation and software content are constantly increasing. Operation is becoming more complex, and at the same time there is a lack of skilled workers who can master this complexity.

- Many machines are used by service providers.

Order-related billing is becoming more and more important. - Local support is often covered by partners whose competences as service providers for different manufacturers are very limited.

- "Fire brigade missions" by the OEM can be very expensive due to a remote location.

The solution: Connected Mobile Machine

To deliver on the performance promises of mobile machines, powerful designs and intelligent system solutions are first required. To ensure availability and performance in operation, Real-Time remote access and monitoring are essential. We offer a complete solution from a single source in cooperation with Ardexa.

Essential core functions of this IoT solution are:

- Remote access via mobile radio and telematics module, incl. remote shell.

- Remote HMI – Visualisation of the HMI in the browser to solve prob-lems together with the driver.

- Remote software update – Update of system and firmware at the push of a button.

- Remote monitoring – Continuous recording of relevant machine and process data. If required, also high-resolution data in the millisecond range.

- Remote analysis – Analysis of recorded data during operation and without intervention in the machine control system. Faults can be detected at an early stage.

- Remote control – Presetting of settings via web interface, without logging into the control system, protected by a secure user system.

- Remote audit – All remote accesses and their actions are logged indelibly.

We help with the electrification of your working machine!

We help with the electrification of your working machine!